Product Features:

1.This laser power supply adopts zero current and half bridge soft switch circuit, it makes the power supply have high efficiency and quick response speed, Thus it is easy to match with Co2 laser tube made by any factories.

2.This laser power supply is easy to be controlled, it is suitable to High or Low level signal. The TTL level can control start or stop of laser output. While the power supply has emergency protection switch which can indicate water through and ventilation.

3.The laser output power can be adjusted by 0-5V analog signal or PWM signal.

4.This laser power supply has open circuit protection function. When protective earthing is good, the laser power supply has open circuit protection function. When protective earthing is good, the laser power supply can be in open circuit status during short time. So that can avoid because of laser tube burst caused by laser power supply.

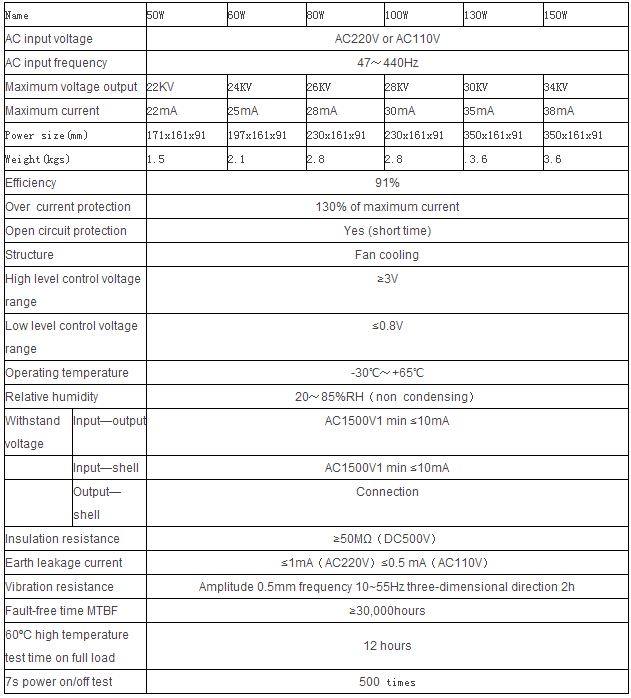

5.Aging test:

Each laser power supply must pass this test which is taken at 60 degree centigrade for 12 hours in full load status, and the power supply must start and stop at each 7 seconds for 500 times. In this way we can ensure the power supply is qualified.

Instructions of Laser Power Supply:

(1) Connection of laser tube

The high voltage (HV+) of the laser power supply shall be connected to the anode (full reflection terminal) of CO2 laser tube. The current circuit of the laser power supply is connected to the cathode (laser output terminal) of CO2 laser tube through an ammeter (or directly).

(2) Connection of control signal

Referring to Figure 1 (or Figure 2), control signal shall be reliably connected to control terminal of the power supply.

(3) Input of control signal

Referring to Figure 1 3, after connecting the DAC output signal and TTL signal of external computer with the power supply, the laser tube shall work as expected.

(4) Voltage

Generally, power input of the power supply shall be 220VAC/50Hz. If 110VAC is needed, please specify when placing order.

(5) Auxiliary function

A group of protection switches are reserved for detection of cooling water, open enclosure protection and so on.

Cautions:

1. The laser tubes shall be cooled by water during working.

2. HV output terminal shall not adopt open circuit! (HV output terminals shall be properly connected to the anode and cathode of the laser tube)

3. Discharge resistance has been equipped inside the power supply and the residual voltage will be fully discharged 2s later after power off. Attentions should be given to avoid any electric shock! (Both output terminals of the high voltage shall ensure the isolation safety of the overhead 40KV.)

4. Three-pole socket with earthing contacts shall be used to laser power supply. The enclosure should be well grounded to avoid electric shock.